India-TMT Optics Fabrication Facility

India is a full-time partner of the global consortium to build the Thirty Meter Telescope (TMT). Out of the 492 segments of the primary mirror, 84 polished mirror segments will be made within the country. To fulfill the stringent requirements and the challenging production rate of the TMT primary mirrors, a special polishing technology known as Stressed Mirror Polishing (SMP) is adopted for the polishing of these mirror segments. Since this technology and the facility to carry out the polishing of mirrors was not available within the country. India-TMT planned to obtain the technology from Coherent, Inc, USA, a company who spearheaded the SMP technology for TMT, JWST, etc. To facilitate this, a world class optics fabrication facility known as India-TMT Optics Fabrication Facility (ITOFF) is built at the CREST campus.

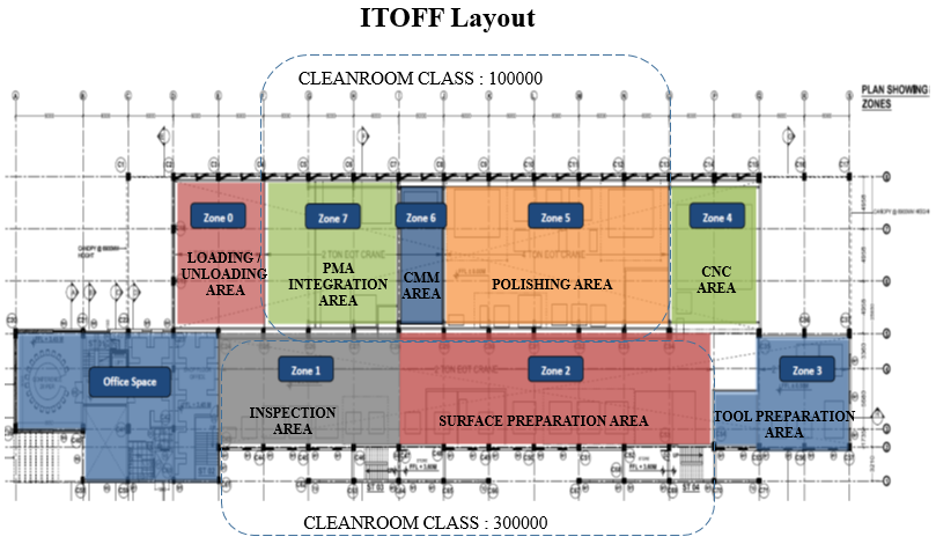

The Facility

The ITOFF building span over 120m x 30m area which is mainly divided into two areas, Office Area and Production Area. The three floor office area consists of 3 conference room and two workstation rooms. The 90m x 30m production area further divided into two class of cleanroom; A 300,000 class cleanroom area for Blank Storage, Surface Preparation and CNC and a 100,000 class cleanroom area for SMP process, Metrology, Co-ordiante Measuring Machine (CMM), Phase Measuring Machine (PMM) and finally to integrate polished mirrors with its electromechanical control system- the SSA, Edge sensors, ACT called the Primary Mirror Assembly.