Mechanical Engineering Division

The Mechanical Engineering Division is a part of the Systems Engineering Group (SEG) of IIA. The main role/objective of the division is to design, prepare detailed engineering drawings and provide necessary technical support for various projects of the institute during installation, testing, commissioning works, including technical support for the backend instrument development based on scientific requirement.

The division has mechanical workshop facilities at the main campus, and at the Vainu Bappu Observatory, Kodaikanal Solar Observatory, and Indian Astronomical Observatory.

Mechanical Design Section

Many design & manufacturing job orders are received at the Mechanical workshop from various ongoing projects at IIA. Some of these need to be designed in-house, carry out Finite Element Analysis (FEM) and release the drawings for manufacturing/ Fabrication. Certain works require close attention and supervision to meet the desired tolerances, accuracies and validation using the existing metrology facility in order to meet the requirements. Mechanical Engineering Design section has the required expertise to take care of all such project demands. Some of the ongoing/recent projects are listed below:

Clamshell Dome Observatory

The 4m diameter Clamshell dome & outer steel structure building was designed in-house. Detailed engineering drawings were prepared, fabricated and installed successfully at CREST Campus of IIA by the Mechanical workshop team at IIA Bengaluru. The Clamshell dome is interfaced over the outer steel structure and houses a 11 inch equatorial fork mount Celestron (CGEPRO 1100) and is designed for public outreach activities. Status: Completed, Feb 2023.

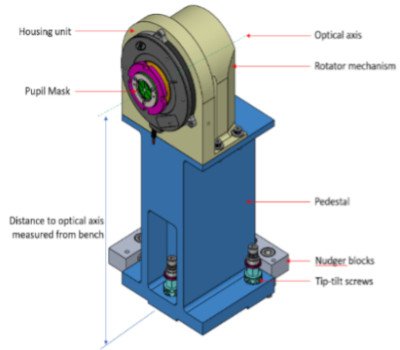

Subsystems for SCALES

IIA is collaborating with University of California Santa Cruz, to build an IR channel for the spectrometer at the Keck observatory in Hawaii. This instrument is called SCALES. Design and fabrication of some of the mechanical subsystems for SCALES are being carried out at IIA. One of the subsystem, called the cold stop rotator assembly is completely manufactured at the Mechanical workshop of IIA using advanced CNC manufacturing methods. Realization of two other subsystems are under progress.

Other on-going activities at the mechanical engineering division include:

- Backend Instrumentation Technical Support for Ground Based observatories of IIA

- Technical support for all the projects of the institute, such as VELC/Aditya-L1, INSIST, TMT, Scales etc.

Mechanical Workshop Facilities

Mechanical workshop support Institute's projects with fabrication and manufacturing of precision components, fabrication of experimental setups, making prototype models for research and project students. The workshop also provides necessary support for the backend instrumentation developmental activities of observatories, and up-gradation of existing facilities. In addition, it also provides technical support for maintenance works of the institute, field stations and guest houses of IIA.

Some of the machinery and facilities available at the mechanical workshop are listed below:

CNC Vertical Machining Centre (VMC)

- Job holding capacity: Machine up to 750 mm x 400 mm (W x L)

- Accuracy: up to 0.001 mm

- Materials: Ferrous & non-ferrous metals

- Operations: Using M-codes and G-codes in Master CAM milling, concave & convex profile milling, drilling, tapping, etc.

Lathe LB17

Make: HMT

Job Holding Capacity: Machine up to diameter of 100 mm x 1000 mm long

Accuracy: up to 0.02 mm

Materials: Ferrous, non-ferrous and non-metals

Operations: Turning, step turning, taper turning, facing, drilling, threading, boring, counter boring, reaming etc.

Lathe LB20

Make: HMT

Job Holding Capacity: Machine up to diameter of 150 mm x 1000 mm long

Accuracy: up to 0.018 mm

Materials: Ferrous, non-ferrous and non-metals

Operations: Turning, step turning, taper turning, facing, drilling, threading, boring, counter boring, reaming etc.

Lathe NH26

Make: HMT

Job Holding Capacity: Machine up to diameter of 500 mm x 1500 mm long

Accuracy: up to 0.02 mm

Materials: Ferrous, non-ferrous and non-metals

Operations: Turning, step turning, taper turning, facing, drilling, threading, boring, counter boring, reaming etc.

Universal Milling Machine

Make: Praga & Gambin

Job Holding Capacity: Machine up to 60 mm wide x 600 mm long

Accuracy: up to 0.002 mm

Materials: Ferrous, non-ferrous and non-metals

Operations: Milling, gear cutting (Spur, helical, herring bone & worm gear), drilling, threading, boring, counter boring, reaming, grooving, slotting etc.

Shaping Machine

Make: Batliboi

Job Holding Capacity: Machine up to 200 mm wide x 500 mm long

Accuracy: up to 0.02 mm

Materials: Ferrous, non-ferrous and non-metals

Operations: Shaping, groove, cuting etc.

Surface Grinding Machine

Make: Alex

Job Holding Capacity: Machine up to 150 mm wide x 400 mm long

Accuracy: 5 microns

Materials: Ferrous and non-ferrous metals

Operations: Grinding

Radial Drilling Machine

Make: HMT

Job Holding Capacity: Drill holes from 0.5 mm to 50 mm and more

Accuracy: up to 0.02 mm

Materials: Ferrous, non-ferrous and non-metals

Operations: Drilling, reaming, etc.

Table Drilling Machine

Make:

Job Holding Capacity: Holes can be drilled up to 25 mm

Accuracy: up to 0.05 mm

Materials: Ferrous, non-ferrous and non-metals

Operations: Drilling

Tool Cutter

Make: JP Machine

Job Holding Capacity: -

Accuracy: -

Materials: Ferrous metals

Operations: Grinding for sharpening of machining tools such as HSS cutting tools, carbide tipped cutting tools, drill bits etc.

All Cutter

Make: IAEC

Job Holding Capacity: -

Accuracy: -

Materials: Ferrous, non-ferrous and non-metals

Operations: Cut raw/machined any size and shape

Power Hacksaw

Make: EIFCO

Job Holding Capacity: Up to 125 mm long

Accuracy: -

Materials: Ferrous, non-ferrous and non-metals

Operations: Cutting

TIG Welding Machine

Make: Electra

Job Holding Capacity: -

Accuracy: -

Materials: Ferrous, non-ferrous metals

Operations: Arc and gas welding of joints

Carpentry Section

There is a small in-house carpentry section facility available within the workshop to provide necessary technical support in fabricating packing boxes/crates, polishing of tables/chairs and maintenance works for the institute. Most of the wood work related requirements including packing of instruments can be handled by this section.

The multi-purpose universal wood planning machine (GS-PAIK make) can perform wood operations such as planning, cutting, line designing, grooving, etc.

People

- Dr. Nagabhushana S (Engineer-F & Head SEG)

- P M M Kemkar (Engineer-F)

- S Kathiravan (Engineer-E)

- Mallappa C (Engineer-C)

- Prasobh P (Mechanic-B)

- K Sagayanathan (Technical Associate B)

- N Thimmaiah (Sr. Mechanical Assistant B)

- Saikat Das (Technical Assistant, Drafting)

- External Contract

- Francis J (CNC Machine operator)

- Ananda T (Fitter)

- Kumar M (Machinist)

- Ananda Kumar (Carpenter)

- Shivananda (Carpenter Assistant)