Prof. MGK Menon Laboratory for Space Sciences

Overview

Prof. MGK Menon Laboratory for Space sciences is designed and built as per ISO 14644-1, 14644-2 and ISO 14644-4 standards to meet the critical molecular and particulate contamination requirements of space-based science instruments. It is on par with international space instrumentation facilities and consists of Class-10 to Class-300000 clean rooms to meet different levels of cleanliness requirements for different activities with an approximate total area of 400 sq.meters.

The facility is equipped with state-of-the-art instruments which can be used to assemble and calibrate optical instruments which require clean-room conditions. The primary purpose of this facility is for testing, integration and calibration of space-based science instruments such as FUV, UV and Visible imaging telescopes, coronagraphs, detectors etc. It also has monitoring facilities for Particulate Contamination, Molecular Contamination, Temperature, Relative Humidity and Positive pressure. It has industrial De-humidifiers which can maintain the RH as low as 20%. All the facility monitoring systems are hooked with Building automation system which has the total remote control ensures fail proof operation.

Payloads

Two major astronomical space payloads which had stringent contamination control requirements were assembled, integrated, calibrated & delivered to Indian Space agency (ISRO) by this facility namely Ultraviolet Imaging telescope (UVIT) on board AstroSat satellite launched in Sept 2015 & Visible Emission Line Coronagraph on Board ADITYA-L1 scheduled to be launched in 2023.

Clean Rooms

Prof. MGK Menon Laboratory houses clean rooms at levels of CLASS-300K, 100K, 10K, 1000, 100 and 10 (ISO-9 to ISO-4).

Class 10 (ISO 4) Clean Room with 20 feet optical table for Payload Integration

Class 100K (ISO 8) Clean room for Contamination Monitoring and Component Testing

Equipments and Instruments

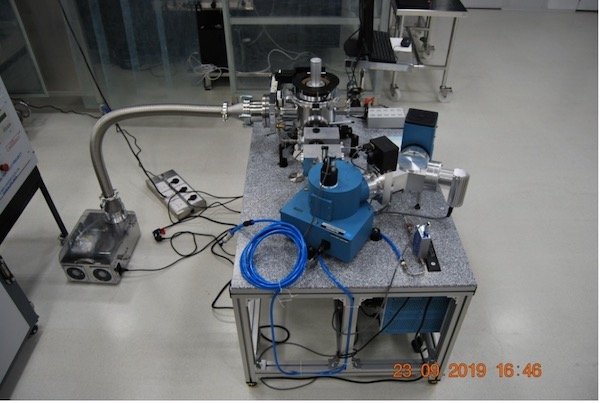

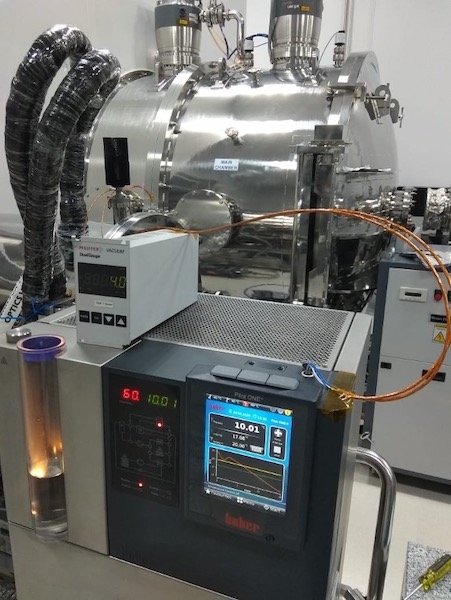

The facility consists of instruments like vibration in sensitive Zygo Interferometer, multiple vacuum calibration facilities including 2.1m (L) X 1.8 m Ø ultra clean payload vacuum chamber with vacuum UV source, Class 10 set up for scatter experiment, Class 10 LAF unit for assembly & Integration, Baking chamber with TQCM setup, Vacuum reflectometer with UV source, Monochromator, Profilo meter, Ultra clean vibration isolation tables, Metrology instruments, Glass desiccators for molecular contamination monitoring, Fume hoods, Ultra clean gas lines with UHP grade GN2 supply, Cleanroom monitoring systems like laser particle counters, PFO meter, ESD protection etc., Cleanroom procedures as per ISO 14644 standards are followed to maintain the laboratory.

Vibration In-sensitive Interferometer for Optical Metrology

Spectrometer for optical Calibration

Profilometer for optical surface Roughness Measurements

Spectro-Photometer for Transmission and Reflection Measurements

Vacuum Chamber for Payload Vacuum Calibration

Baking Chambers for Molecular Contamination Removal

Molecular Contamination Measurement Facilities

Thermal Conditioning Unit for Payload Detector Calibration