The Optics Division

Optical Design

IIA Optics design team is equipped with various design and analysis packages that are being used for various astronomical instrumentation programs. The team is proficient in software such as tracePro, Zeemax Optics Studio, G-Solver and ASAP.

Some of the recent projects include:

- TMT Backend Instruments and Stress mirror polishing

- National Large Optical Telescope (NLOT)

- Indian Spectroscopic and Imaging Space Telescope (INSIST)

- Star Tracker Unit - Optical head unit

- Multi-Object Spectrograph and Intergral field Unit

Optics Fabrication

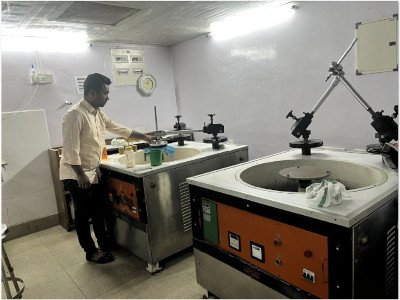

IIA Optics Laboratory is equipped with a 700 mm grinding and polishing machine to take glass polishing to a size from 25 to 600 mm. The laboratory has a metal mirror polisher to a size of 300 mm. Glass slitting machine is used for slicing the glass blanks and a drilling machine for bunking glass slabs. A Thermal chamber is being used for pitch tool preparation.

Recent Projects:

- PSMT Mirror fabrication

- TMT Mirror segments fabrication

- SING Mirrors fabrication

- BARC Mirror Polishing

- Prism fabrication

- IFU Lens fabrication

Glass Grinding Machine

Glass Polishing Machine

Metal Polishing Machine

Glass Slitting Machine

Glass Drilling Machine

Thermal Chamber

Optics Metrology

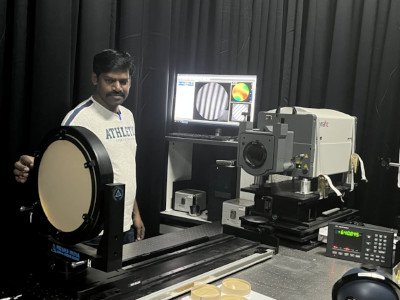

Optics laboratory is equipped with an interferometer from ZYGO for measuring the surface figure of an optical surface and system wavefront error. The interferometer is placed over a 20 feet vibration isolation table. High frequency error of the optical surface (surface roughness) is measured by profilometer metrology tool. The surface radius of curvature is measure by Spherometer, the cosmetic quality check is done with a magnifier.

ZYGO Dynafiz Interferometer

Spherometer

S E M

Veeco Roughness Profilometer

Optics Coating

BC 300 Box Coater

BC300 box coater is capable of performing multi-layer coating (metallic and dielectric) of thin film material on an optics of maximum 6 inch diameter by DC and RF sputtering.

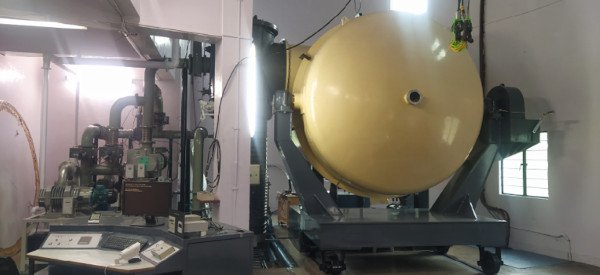

2.8m Coating Chamber at VBO Kavalur

The VBT Mirror coating plant at VBO consists of a cylindrical, stainless steel high vacuum chamber of diameter 280cm and length of 300cm. The chamber can house mirrors upto 230cm in diameter and a maximum weight upto 4000kg. The largest optics being aluminized in the coating plant is 234cm in diameter and ~ 35cm thickness which is the VBT primary mirror.

1.5m Coating Chamber at VBO Kavalur

The 60 inch Aluminization plant at VBO consists of a high vacuum chamber of diameter 152 cm and length of 254 cm. The chamber can house mirrors upto 127 cm in diameter and a maximum weight of 700 kg.

2.0m Sputtering Unit, IAO

2m Sputtering unit at Hanle works on the principle of RF magnetron sputtering is used for the aluminization of the 2m HCT Mirror. HCT Primary Mirror has a diameter of 2032mm with and weighs around 694kgs.

Astronomy Instrumentation

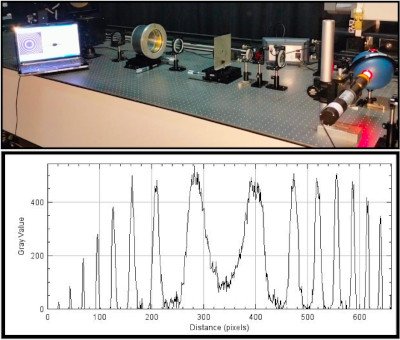

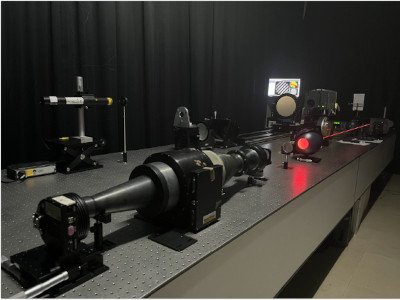

Fabry-Perot Interferometer

Design and Development

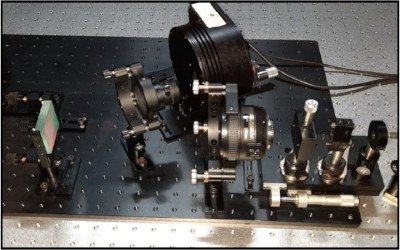

DMD Spectrograph

Alignment and Testing

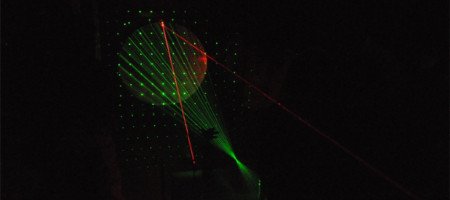

Integral Field Unit

Multi-object spectroscopy

Star Tracker Head Unit

Alignment and Calibration

Outreach and Education

Team Members

- S Sriram (Engineer-F, head of the Division)

- Totan Chand (Engineer-B)

- Alikhan Basheer (Engineer-B)

- Remya B S (Sr. Technical Assistant)

- Rahuldeb Burman (Technical Assistant)

- Project Staff

- Amirul Hassan (Project Engineer-II)

- Nataraj G (junior Technician)

- Chethan C (Junior Technician)